MVR Evaporator System

Menu

Latest News

Product introduction

Efficient treatment of different types of solutions

- MVR evaporators

MVR evaporators are used in the manufacturing industry and various industries. The introduction of evaporation equipment into production helps to save resources and reduce costs: clean distilled water is returned to production, and less money is needed for waste treatment. MVR evaporators can be used for liquid treatment in plants producing inorganic salts, nitrogen fertilizers, paint and varnish industry, electroplating production, pharmaceuticals, and confectionery factories. The technology can significantly reduce the amount of waste treatment.

What can MVR evaporators bring?

- Provides evaporation of solutions with a wide range of capacities.

- There is no waste heat steam discharge, and the energy-saving effect is very significant.

- Reduced energy costs compared to single-shell units.

- Only a very small amount of raw steam is required.

- Fully automatic operation, continuous operation.

MVR evaporator system profile

MVR steam compressor engineering is a Steam digital compressor (intrusion engineering) mute. An evaporator is an energy-saving technology that reuses energy from the secondary steam itself to reduce the need for external energy.

MVR is evaporated by the steam compressor (or fans) the secondary steam after the evaporator and compressed to increase the value of atrophy, enthalpy increases after the secondary steam is sent into the heating room as a source of food heat again, The Heat stage converts to condenser water. The heating material is enriched by steam and then it releases the system.

MVR evaporator system

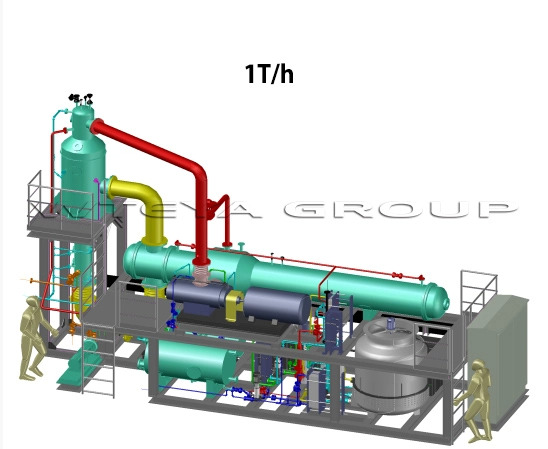

MVR evaporator, separator, compressor, vacuum pump, circulation pump, operation platform, electrical tools that control cabinets and valves, tubes, and other systems.

MVR evaporator system specification

1. mv energy moving evaporator just needs very lneedsapor, significantly reduce operreducescost, reduce envied reducestal pollution. No hot steam waste, energy-saving effect is very noticeable.

2. Because the steam compressor provides, compared to the traditional evaporators, the evaporators 'nature is much smaller, it can reach a gentle vapor, significantly improve the product quality, reduce soil, and.

3. the structure and process are very simple, fully automatic, can run continuously, safe and reliable, le.

4. fit with pipe cleaning CIP, you can clean, appliances are complete, no dead corner. No corner seam waste, energy-saving effect is very noticeable.

5. A single effect and many effectiveness of materials applicable, suitable for the use of MVR evaporator, in the excellent replaceable technology, and have better properties of the environment and energy saving.

MVR evaporator system

MVR evaporating system is widely used in many industrial areas, especially in the necessary areas of evaporator process, effective starch, and enriched energy. The specific applications include:

1. Chemical industry: in chemicaoduction, usually need to confederate or extract pure solvents, the MVR evaporator technology can achieve these processes efficiently while reducing energy consumption.

2. Environment: For high saline sewage, purification wastewater wastewater, and environmental management problems, MVR evaporator technology provides an efficient solution. It can help to reduce the pollution and meet the environmental standards.

3. New energy industry: some production processes in the new energy industry, such as battery production, also need to use evaporator technology to recycle or clean the materials.

4. The food industry: in the food processing process, MVR evaporation tor can be used for liquids such as concentrated fruit juice, and syrup, important over product concentration while retaining the original flavor.

5. Charcoal chemical: tap chemical storage waste, steam MVR can efficient wastewater treatment and recycling.

6. Electric Industry: such as waste disposers, Mdisposersrator can help to reduce processing costs and improve the use of water cycle.

7. Electroplate industry: The waste wwatwatertewaterelectroplate process contains heavy metal and other harmful substances, the MVR evaporative technology can be used for toxic waste cleaning and recycling.

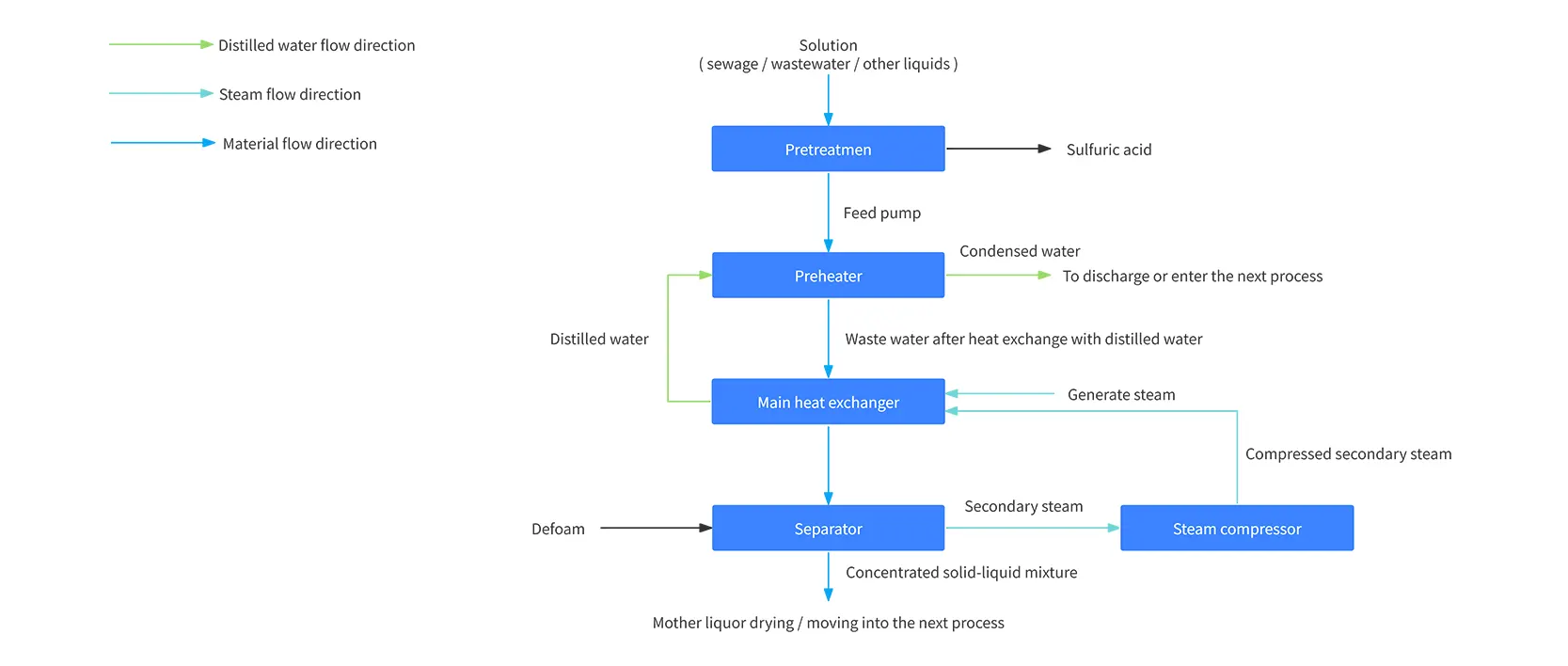

Technical principle of

MVR steam mechanical recompression technology is the abbreviation of mechanical vapor recompression technology. MVR evaporator is an energy-saving technology that reuses the energy of the secondary steam it produces, thereby reducing the demand for external energy.

MVR evaporator uses a mechanical compressor (or fan) to recompress the evaporated secondary steam to increase its enthalpy value. The secondary steam with increased enthalpy value is sent to the heating chamber again as a heat source to heat the feed, and its exothermic phase changes into condensed water and is discharged. The heated material is discharged from the system as the final product after vaporization and concentration.

The production process of

MVR system evaporation process:

A. Feeding process:

The wastewater raw liquid is sent to the preheating system through the feed pump to exchange heat with distilled water for heating, and the heated wastewater raw liquid enters the separator.

B. Evaporation process:

After entering the separator, the wastewater raw liquid is sent to the heater through the circulating pump, and heat is exchanged with the high-temperature secondary steam. The secondary steam condenses into water and enters the distilled water tank. The circulating liquid absorbs the heat of the steam, flashes in the separator, and separates the gas and liquid. The concentrated liquid is returned to the evaporator by the circulating pump to continue evaporation until the predetermined concentration is reached.

C. Discharging process:

When the predetermined evaporation concentration is reached, the system controls the discharging.

Non-condensable gases are automatically discharged through system control.

D. Drainage process:

The distilled water temporarily stored in the distilled water tank is transported to the preheating system through the distilled water pump, exchanges heat with the wastewater raw liquid for cooling and then is sent out of the system.

Production of equipment

For more than ten years, the company "WTEYA" has been designing and manufacturing a range of evaporation equipment. Evaporation equipment effectively solves the problem of wastewater treatment by dehydration.

Introducing evaporation equipment into production helps save resources and reduce costs: clean distilled water returns to production, and less money is needed for waste treatment. Various models of evaporation equipment, if you need, we can customize, OEM&ODM service.

MVR evaporator costing

How much does a Mechanical Vapor Recompression evaporator cost? To calculate the cost accurately, we recommend that you fill out a questionnaire and then we will be able to prepare a commercial offer, taking into account all the features of your project. We are always ready to provide you with detailed information about the different models, their technical characteristics, performance. We offer a full range of services, from advice and assistance in selecting equipment to its supply, installation, and configuration. Our goal is to provide you with the necessary equipment to effectively solve the water treatment problem in your specific situation.

So, you need to email us at info@wteya.com

Our manager will prepare an excellent quote for you

Capacity and size

|

MVR system parameter table |

|||||

|

Evaporation(t/h) |

Evaporative way to make |

Total energy (kW/h) |

Steam consumption (t/h) |

Reuse water consumption (t/h) |

Area(LWH/m) |

|

0.5 |

MVR, loop required |

70 |

0-0.03 |

10 |

6*3*5 |

|

1 |

MVR forced circulation |

110 |

0-0.05 |

10 |

9*8*6 |

|

1.5 |

MVR forced circulation |

180 |

0-0.05 |

20 |

12*7.5*9 |

|

2 |

MVR forced circulation |

213.5 |

0-0.1 |

30 |

12*8*10 |

|

3 |

MVR forced circulation |

275 |

0-0.1 |

50 |

15*8*15 |

|

5 |

MVR forced circulation |

425 |

0-0.2 |

50 |

15*10*15 |

|

7.5 |

MVR forced circulation |

580 |

0-0.3 |

70 |

15*12*15 |

|

10 |

MVR forced circulation |

815 |

0-0.3 |

100 |

12*6*18 |

|

Heater parameter table |

||||

|

Evaporation(t/h) |

Heat exchanger type |

Specifications |

Material |

Quantity |

|

0.5 |

Horizontal double-pass, forced circulation |

S=50m²,∅500×6000×5mm |

TA2 |

1 |

|

1 |

Horizontal double-pass, forced circulation |

S=100m²,∅650×6000×5mm |

TA2 |

1 |

|

1.5 |

Horizontal double-pass, forced circulation |

S=150m²,∅800×6000×5mm |

TA2 |

1 |

|

2 |

Horizontal double-pass, forced circulation |

S=200m²,∅800×6000×5mm |

TA2 |

1 |

|

3 |

Horizontal double-pass, forced circulation |

S=260m²,∅1000×6000×5mm |

TA2 |

1 |

|

5 |

Horizontal double-pass, forced circulation |

S=450m²,∅1300×6000×6mm |

TA2 |

1 |

|

7.5 |

Horizontal double-pass, forced circulation |

S=650m²,∅1500×6000×6mm |

TA2 |

1 |

|

10 |

Horizontal double-pass, forced circulation |

S=880m²,∅1800×6000×8mm |

TA2 |

1 |

Chart of effect chart

Frequently Asked Questions

Q: Does MVR force the evaporator to run?

Cause: could be the corrosion of secondary steam pipes or steam compressors, pure water quality does not meet the standards, or at the point of equipment such as welding, flange, sealing, expansion, and so on.

Solution: ensure water quality to standards, regularly clean the system, maintain stable cooling water temperature, and provide a complete amount of cooling water.

Problem: MVR is required to deflate slow feeding or a small flow situation?

Reason: usually due to the filter being blocked.

Solution: inspection and purification of filters.

Q: The steam reduction charged by MVR?

Cause: this could be due to system clogging or dirt in the hot water catheter.

Solution: do online purification programs for cleaning dirt.

Q: The effect of the steam valve charged by MVR?

Cause: The material is processed after thickening, usually, resulting in clogging.

Solution: The Prevention includes a regular filter of salt and spray as well, once stuck, use juice or vacuum treatment.

Q: MVR compulsory evaporator effect?

Expression: Produces regular and loud sound, and vibrates the pipes.

Solution: Constant current stability compressor when the counter rate is soft and open the valve through the appropriate rate; the counter rate needs to close the compressor immediately for testing, and pay attention to liquid temperature to avoid counter rate.

Q: cool MVR evaporator doesn't work properly?

Cause: could be due to too thick dust, or vacuum drop.

Solution: add agent foaming agent, check detector and dehumidifying liquid, import steam valve adjustment, and vacuum control.

| S/N | Single effect evaporator | Multi-effect evaporator | TVR evaporator | MVR evaporator |

|---|---|---|---|---|

| Energy source | Using steam heating Steam pipe network Need boiler |

Using steam heating Steam pipe network Need boiler |

Need high-pressure steam to drive, Need boiler |

Using electric power, no need steam pipe network close loop circulation system |

| Energy consumption | 1-ton steam for 1ton water evaporation | 0.3~1tons steam for 1ton water evaporation | Based on traditional multi-effect, one more effect is used with a high-pressure steam drive | The most energy-saving technology at present |

| Operation cost | Much higher | More energy saving | Lower | Lowest |

| Footprint | smaller | bigger | bigger | smaller |

| Product Quality | Short residence time, Bigger temp. The difference leads to an easy scale. product quality is not stable |

Longer residence time, Bigger temp. The difference leads to an easy scale. product quality is not stable |

Short residence time, Smaller influence on product quality |

Short residence time, Low temp. evaporation, Minimum impact on product quality |

| Control type | Semi-automatic | Full automatic Uninterrupted evaporation |

Full automatic Uninterrupted evaporation |

Full automatic Uninterrupted evaporation |

Previous: Industrial Evaporator Manufacturers

Next: No More