Practical Guide for Small and Medium Enterprises: How can MVR evaporators reduce costs and increase efficiency to improve wastewater treatment efficiency?

For many small and medium-sized enterprises, wastewater treatment is a costly and difficult challenge. Especially when faced with high-salt or high-concentration industrial wastewater, companies often have to bear high energy consumption expenditures while also responding to increasingly stringent environmental protection requirements. In recent years, an efficient and energy-saving technology - MVR evaporator (mechanical vapor recompression) is gradually becoming a new choice for wastewater treatment, especially for companies pursuing high cost-effectiveness and low operating costs.

✅ What is an MVR Evaporator, and why does it save money?

The principle of MVR evaporator is to recycle the steam generated during the evaporation of wastewater, and then compress it through a steam compressor to increase the temperature and pressure, so that it becomes the heat source for the next evaporation cycle, thereby recycling heat energy and greatly reducing energy consumption. Compared with traditional multi-effect evaporators, MVR does not need to continuously input external steam, which greatly reduces operating costs.

Popular understanding: Just like hanging clothes, the traditional method is to blow hot air continuously, while MVR is like collecting hot air and using it repeatedly, which greatly saves energy.

✅ What Wastewater is MVR Suitable for Treating?

MVR evaporator is particularly suitable for the following types of industrial wastewater:

Chemical wastewater - high salt (such as sodium chloride, sodium sulfate)

Pharmaceutical wastewater - high COD, high organic matter concentration

Food processing wastewater - such as soy sauce, monosodium glutamate, and other concentrated liquids

Metal surface treatment wastewater - containing nickel, chromium, acidic liquids, etc.

Unsuitable scenarios: high viscosity wastewater, silicon-containing, or toxic volatile substances.

✅ Cost Analysis: Investment vs. Operation

Initial investment

A production line with a daily output of 10-50 tons costs between 1 million and 5 million yuan, depending on the material (e.,g. stainless steel, titanium) and the degree of automation. However, some local governments may provide subsidies of up to 30%.

Example of operating cost (taking 20 tons/day as an example)

|

Cost Items |

Traditional evaporator |

MVR Evaporator |

Savings |

|

Steam Fees |

¥80,000/monNo |

no need |

Save more than 95% |

|

Electricity |

¥10,000/month |

¥30,000/month |

Although the electricity bill is higher, the total cost is lower |

Although MVR consumes more electricity, its overall operating cost is still significantly lower than traditional equipment because it requires almost no steam.

✅ Which SMEs are Suitable for MVR?

✅ Wastewater is highly concentrated or high in salt

✅ Daily handling capacity: 10~200 tons

✅ Enterprises lack stable and low-cost steam resources

If the processing volume is too small (<5 tons/day) or the wastewater is too dilute, pre-concentration or other alternative processes can be considered.

✅ Procurement Advice for SMEs

Conduct a small test first – It is recommended to experiment to verify the treatment effect first.

Flexible financing plan – You can consider leasing, third-party operation, and other methods to reduce initial investment.

By-product resource recovery – By-products such as sodium chloride can reach industrial standards and have the opportunity to sell them to recover costs

✅ Why Choose WTEYA Group?

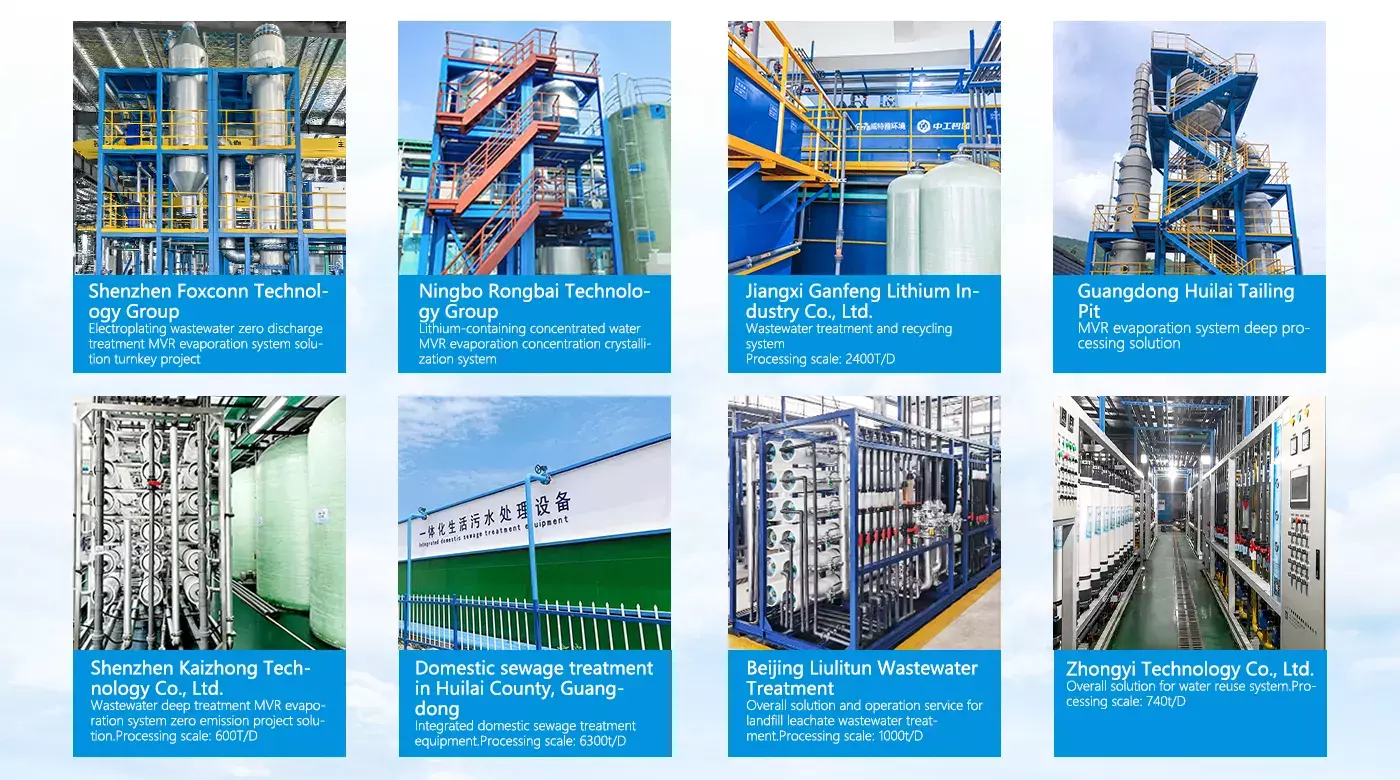

WTEYA is a brand you can trust. With more than ten years of rich experience, we have provided efficient and reliable water treatment solutions to many well-known companies around the world. We have successfully implemented projects for listed companies such as Foxconn, Huawei, Ganfeng, and Rongbai, with more than 100 project cases, and have won the trust and praise of customers. We support OEM & ODM customization and customized solutions to meet your unique needs.

✅ WTEYA is Recruiting Agents!

Welcome to join us. As a 16-year-old brand, WTEYA provides you with a variety of preferential policies, professional training guidance, and all-round technical support, which is worthy of your trust!

*Email: info@wteya.com

*WhatsApp:+86-18002840855

Let us help you achieve unparalleled water quality!