Domestic sewage treatment system project case

Project information

Project name: Huilai County Shenquan Town sewage treatment plant integrated sewage treatment equipment purchase and installation project

Project address: Shenquan Town, Huilai County, Guangdong Province

Project scale: The total construction scale of Shenquan Town sewage treatment plant in Huilai County is 3000t/d

Project background:

Shenquan Town is located in the southeast of Huilai County, 9 kilometers away from the county seat. At present, the town is under construction in Shenquan Town, Jinghai Town, Longjiang Town sewage treatment plant and supporting pipe network PPP project, including a Shenquan town sewage treatment plant (recent plan 5000m³/d, long-term scale 10000m3/d) and supporting pipe network 4.1 kilometers. Due to the conflict between the preliminary design of the site selection of Shenquan Town sewage treatment plant and the planning of East Guangdong New City, the site selection of the sewage treatment plant cannot be implemented. In order to solve the sewage treatment problem after the completion of the sewage collection system in Shenquan Town recently, it is urgent to build temporary sewage treatment facilities to centrally treat the collected sewage and discharge it to the standard, so as to reduce the pollution load of the nearby river and protect the water resource environment of Shenquan Town. Ensure the safety of drinking water.

In order to speed up the construction progress and avoid the re-acquisition of land, the open space in Shenquan Port Office is used to construct temporary integrated sewage treatment facilities.

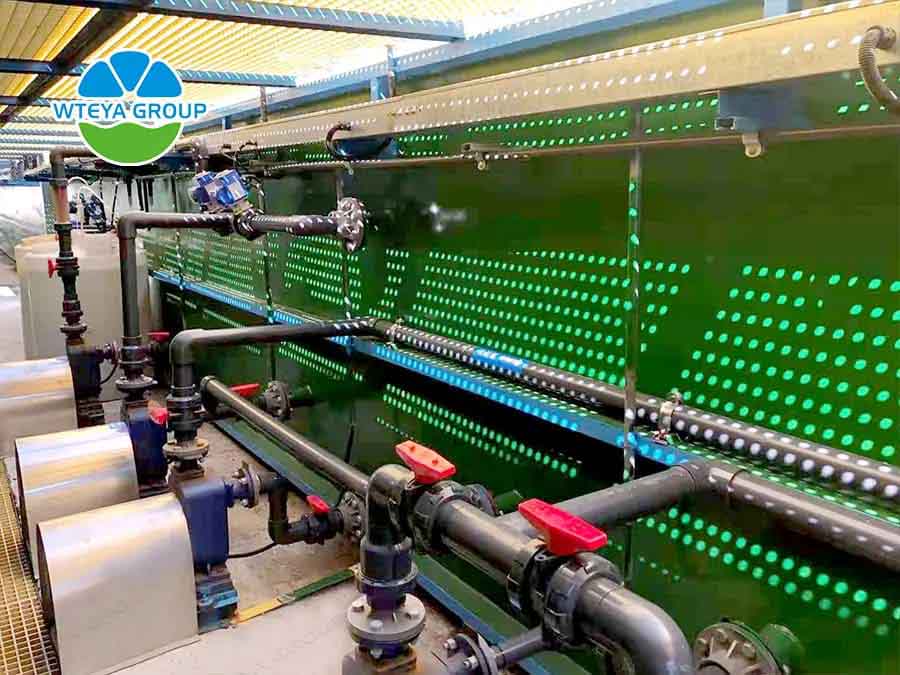

Taking into account the tight construction period and short design life of the project, the main sewage treatment process of the project is intended to adopt integrated treatment facilities. Treatment of sewage collected by the network as a temporary measure pending the implementation of the new sewage treatment plant. After the completion of the new sewage treatment plant, the integrated sewage treatment facility can be dismantled.

Discharge standard: The effluent quality of the integrated domestic sewage treatment facility of this project shall be implemented according to the national and A standards.

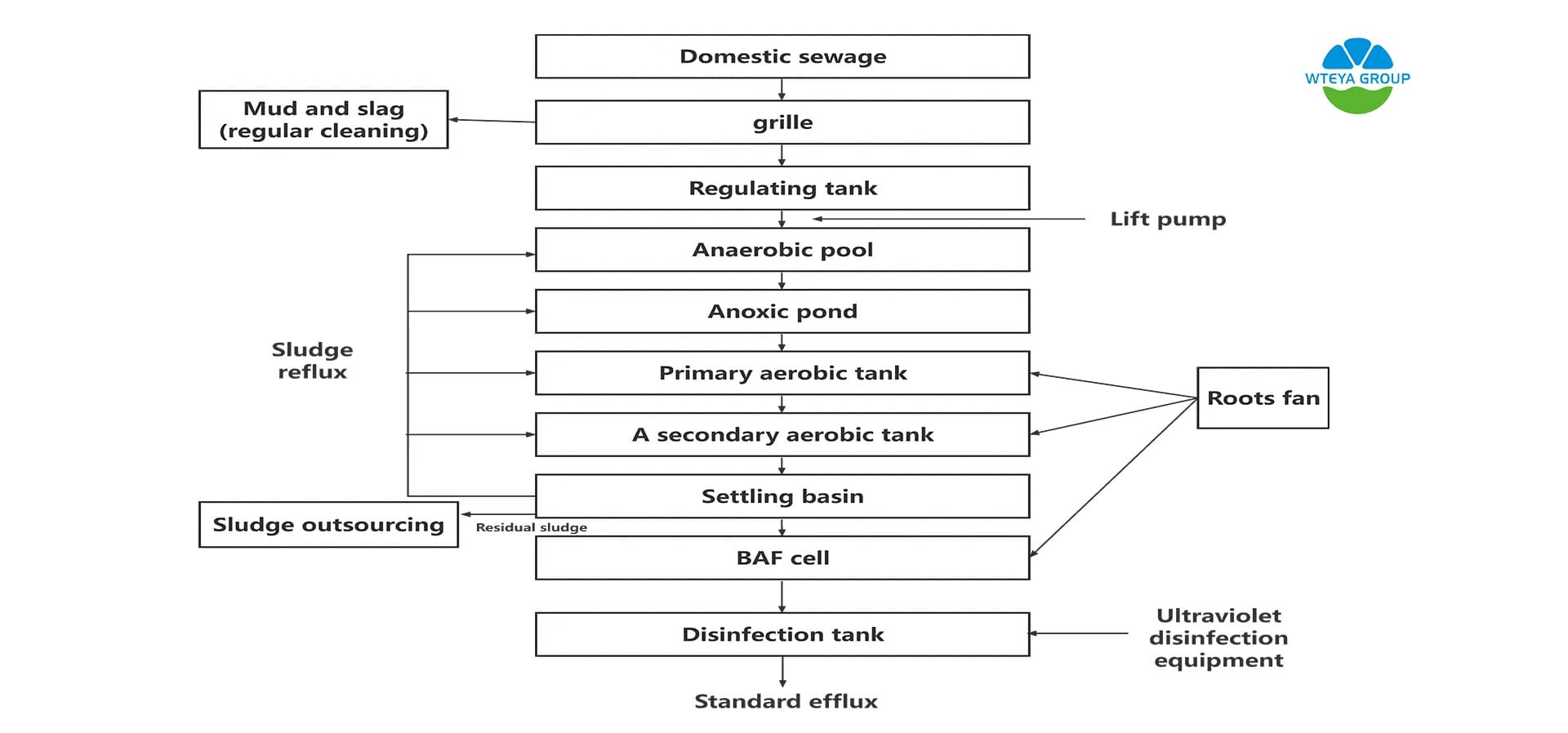

Urban sewage treatment process: The process combination of the urban sewage treatment system of this project is "regulation tank + anaerobic tank + anoxic tank + primary aerobic tank + secondary aerobic tank + sedimentation tank +BAF+ disinfection".

Process flow

Process characteristics

The A2/0 process is to add an anoxic pool to the anoxic pool, and return part of the mixture liquid flowing out of the aerobic pool to the front of the anoxic pool to achieve the purpose of nitrification and nitrogen removal. The synchronous phosphorus and nitrogen removal mechanism of A2/0 method consists of two parts: First, phosphorus removal, phosphorus in the sewage in the anaerobic state (DO<0.3mg/L), the release of phosphorus accumulation bacteria, and in the aerobic condition more absorption, in the form of residual sludge discharge system. The second is nitrogen removal. DO<0.5mg/L should be controlled in the anoxic section. Due to the role of aerobic denitrification bacteria, BOD in water is used as a hydrogen supplier (organic carbon source) to reduce nitrate and nitrite from the aerobic pool mixture into nitrogen and escape into the atmosphere to achieve the purpose of nitrogen removal.

Biological aerated filter (BAF) technology is developed on the basis of fully absorbing the advantages of foreign biological aerated filter, its biggest feature is the use of a new type of spherical ceramic filler, on its surface and open inner cavity space to grow microbial membrane, sewage from the bottom up through the filter layer, The microbial membrane absorbs organic pollutants in the sewage as nutrients for its own metabolism, and provides aeration for oxygen in the lower part of the filter material layer, and the gas and water are in the same upward flow state, so that the organic matter in the wastewater can be aerobic degradation and denitrification can be carried out. It regularly uses the treated water to backwash the filter to eliminate the aging microbial film proliferated on the surface of the filter material to ensure the activity of the microbial film.

- The process can be called the simplest synchronous nitrogen and phosphorus removal process in the system, and the total hydraulic residence time is less than other processes.

- In the anaerobic, anoxic, aerobic alternating operation conditions, filamentous bacteria can not prolifitate, not easy to occur filamentous expansion of sludge, SVI value is generally less than 100.

- The sludge contains high phosphorus and has high fertilizer efficiency.

- The floor area is small, usually 1/5-1/10 of the floor area of the conventional treatment process, the factory layout is compact and beautiful.

- The treatment of effluent quality is good, can meet the water quality standards or domestic water quality standards.

- The process is short, the oxygen transmission efficiency is high, the oxygen supply power consumption is low, and the power consumption of the treatment unit sewage is low.

- The filtration speed is high, the processing load is much higher than the conventional processing process.

- Strong impact resistance, small impact by climate, water and water quality changes, especially suitable for cold weather areas, and can be run intermittently.

- Can be built closed workshop, reduce odor, noise on the surrounding environment, visual sensory effect is good.

- Convenient operation and management, easy maintenance.

- All modular structure, convenient for later reconstruction and expansion.