Tube Bundle Heat Exchanger: High-Efficiency Cooling

Menu

The Industrial Workhorse,

Re-engineered.

The WTEYA Shell & Tube Heat Exchanger isn't just a component; it's the heart of a reliable process. Built for durability and performance, it is the definitive solution for demanding applications where uptime and process purity are non-negotiable

Handles Tough

Media

Perfectly suited for slurries, viscous fluids, and high-particulate streams that cripple other exchangers.

Extreme Condition

Ready

Built to withstand high pressures and temperatures, ensuring safety and a long service life.

Fouling-Resistant

by Design

Engineered for smooth flow paths that minimize deposit buildup and clogging.

Gasket-Free

Integrity

Fully welded construction eliminates leaks, contamination risks, and gasket maintenance.

Get the Right Solution for Your Process

The cost of a tube heat exchanger depends on factors like materials, size, and pressure ratings. A generic price won't solve your problem—a custom solution will. In order to calculate the cost accurately, we recommend that you fill out a questionnaire and then we will be able to prepare a commercial offer, taking into account all the features of your project. We are always ready to provide you with detailed information about the different models, their technical characteristics, performance. We offer a full range of services, from advice and assistance in selecting equipment to its supply, installation and configuration. Our goal is to provide you with the necessary equipment to effectively solve the water treatment problem in your specific situation.

Let's Engineer Your Solution.

So, you need to email us at info@wteya.com

Our manager will prepare an excellent quote for you

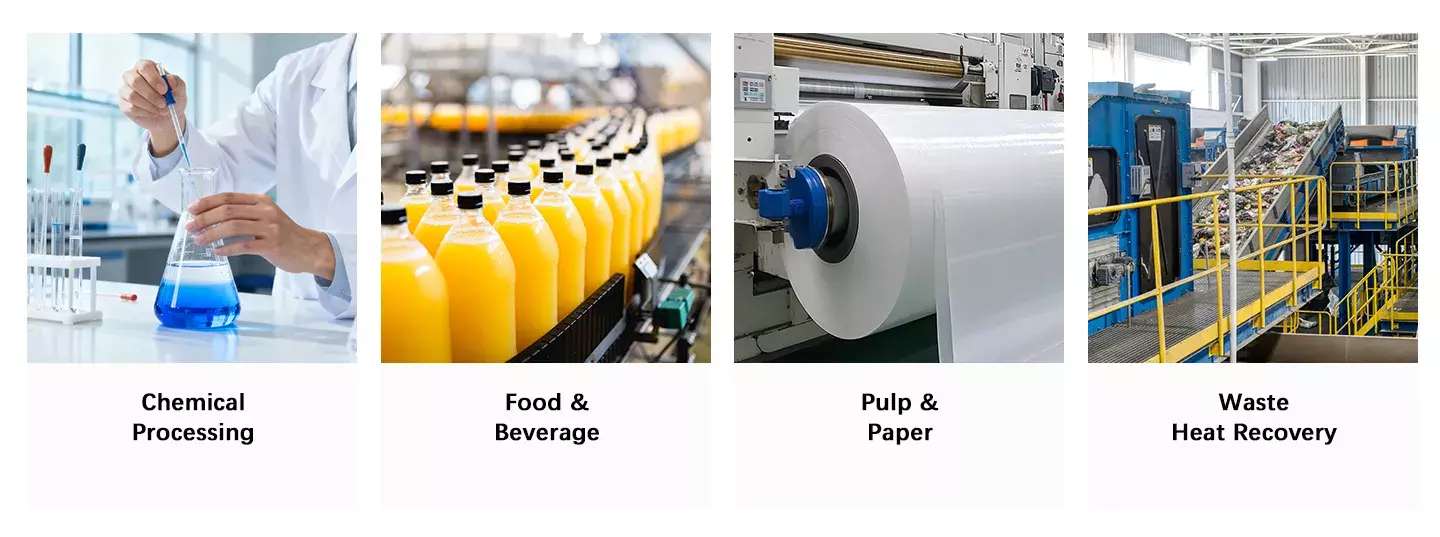

Engineered for Your Industry's Toughest Jobs

WTEYA Group tube heat exchangers are trusted in the most demanding environments where other technologies fail. We have successfully implemented numerous tubular heat exchangers, evaporation systems in various industries and have a large database of proven technical solutions.

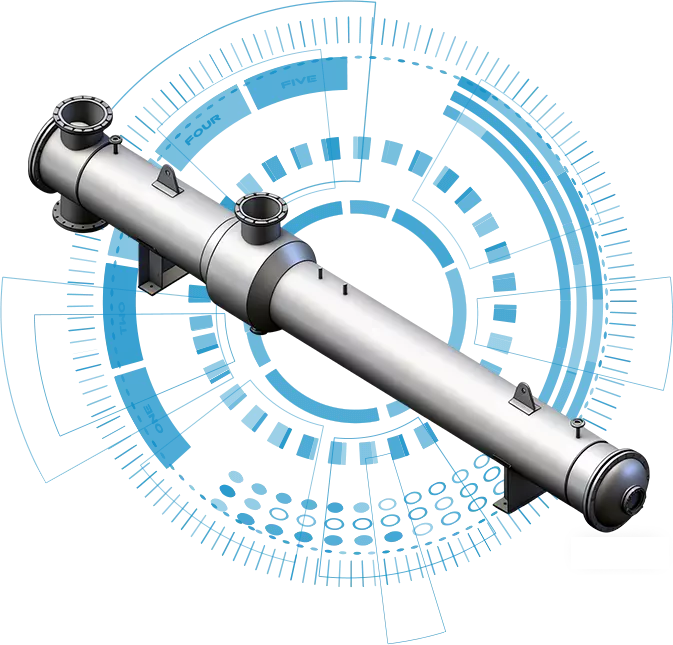

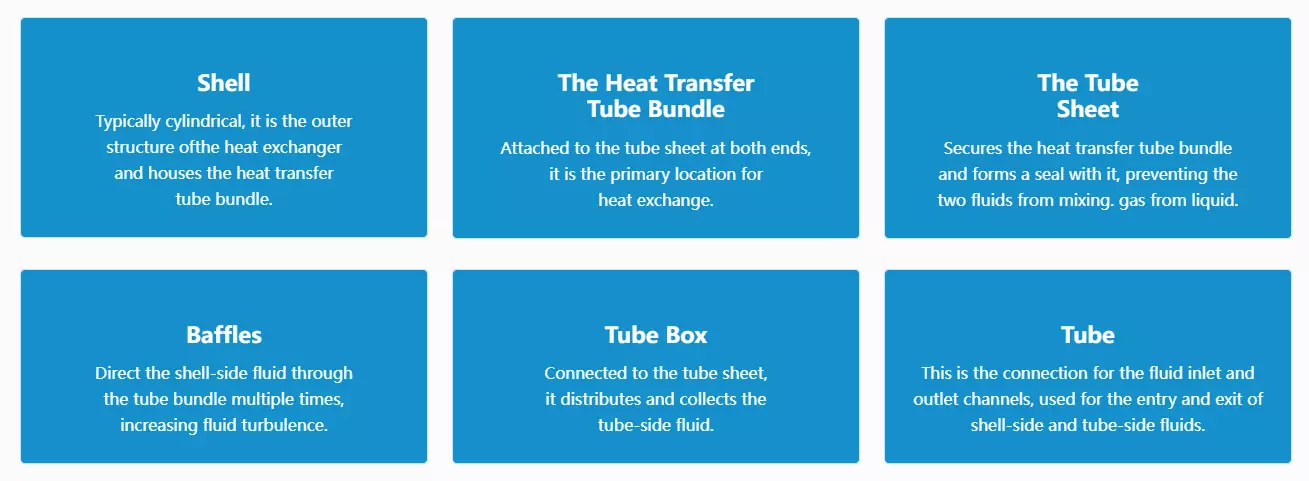

What does it consist of?

Shell-and-tube heat exchangers primarily consist of a shell, heat transfer tube bundles, tube sheets, baffles (damper plates), and tube boxes. We offer a comprehensive range of rigorously tested, standardized products with stable performance to meet a wide range of industry needs.

We also offer customized services such as OEM and ODM, with our professional design team providing tailored solutions to meet unique customer needs.

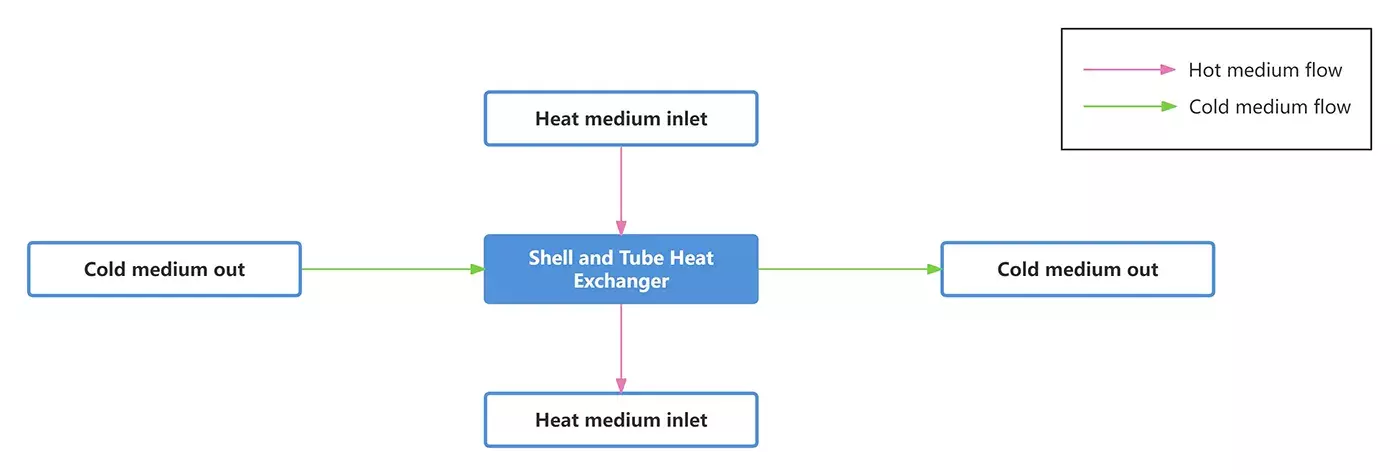

How it works

The technical principle of a shell-and-tube heat exchanger is primarily based on inter-wall heat exchange. In this process, one fluid flows through the interior of the tube bundle, while another fluid flows in the shell outside the bundle, exchanging heat through the tube walls. Specifically, the working principle of a shell-and-tube heat exchanger includes the following aspects:

1. Heat transfer surface: The tube walls serve as the heat transfer surface, with the two working fluids flowing inside and outside the tubes, respectively, exchanging heat through the tube walls.

2. Fluid flow: The tube-side fluid flows within the tubes, while the shell-side fluid flows outside. To improve the heat transfer efficiency of the tube-side fluids, some designs utilize spiral or corrugated tubes. These specially shaped tubes increase fluid turbulence, thereby improving the heat transfer coefficient.

3. Temperature control: By adjusting the flow rate of the heat source entering the heat exchanger, the temperature of the heated medium can be controlled. For example, a regulating valve is placed before the heat source inlet; varying the valve opening adjusts the outlet temperature.

Product Parameters

|

Basic Parameter Table (Outer Diameter Of Heat Exchange Tube Ø20) |

||||||||

|

Nominal diameter |

Number of heat exchange tubes |

Center arrangement tube |

Pipe flow area |

Calculate the heat transfer area |

||||

|

1500 |

2000 |

3000 |

4500 |

6000 |

||||

|

159 |

15 |

5 |

0.003 |

1.4 |

1.9 |

2.8 |

|

|

|

219 |

33 |

7 |

0.0066 |

3.1 |

4.1 |

6.2 |

|

|

|

273 |

65 |

9 |

0.013 |

6.1 |

8.2 |

12.3 |

18.4 |

24.5 |

|

325 |

99 |

11 |

0.0199 |

9.3 |

12.4 |

18.7 |

28 |

37.3 |

|

400 |

174 |

14 |

0.035 |

16.4 |

21.9 |

32.8 |

49.2 |

65.6 |

|

500 |

275 |

19 |

0.0553 |

|

34.6 |

51.8 |

77.8 |

103.7 |

|

600 |

433 |

21 |

0.136 |

|

54.4 |

81.6 |

122.5 |

163.2 |

|

700 |

595 |

25 |

0.187 |

|

74.7 |

112.1 |

168.2 |

224.3 |

|

800 |

769 |

29 |

0.242 |

|

96.6 |

144.9 |

217.4 |

290 |

WTEYA Manufacturer

WTEYA pursues digital and intelligent manufacturing to provide customers with excellent products and services. We not only provide a series of standardized products that have been rigorously tested and have stable performance to meet a wide range of industry needs. We also provide OEM&ODM customized services to meet the unique needs of customers.