Sea water desalination system

Menu

Seawater Desalination Plants: Clean Water For All

The purpose of a desalination system is to clean or purify brackish water or seawater.

The desalination plant is by far our most popular water maker. It is a very simple and highly reliable system that can produce up to 140 litres of fresh drinking water per hour.

|

WTY-SWRO-3.0MPH |

WTY-SWRO-20.0MPH |

|

WTY-SWRO-5.0MPH |

WTY-SWRO-25.0MPH |

|

WTY-SWRO-10.0MPH |

WTY-SWRO-30.0MPH |

|

WTY-SWRO-15.0MPH |

WTY-SWRO-40.0MPH |

Are you still worried about

the shortage of water resources?

There is a shortage of fresh water resources, or in emergencies such as earthquakes or floods, fresh water cannot be obtained immediately.

Six advantages Hardcore upgrade

When you want to make a lot of water quickly, turn salt water into fresh water or drinking water. Our desalination plant is a good choice.

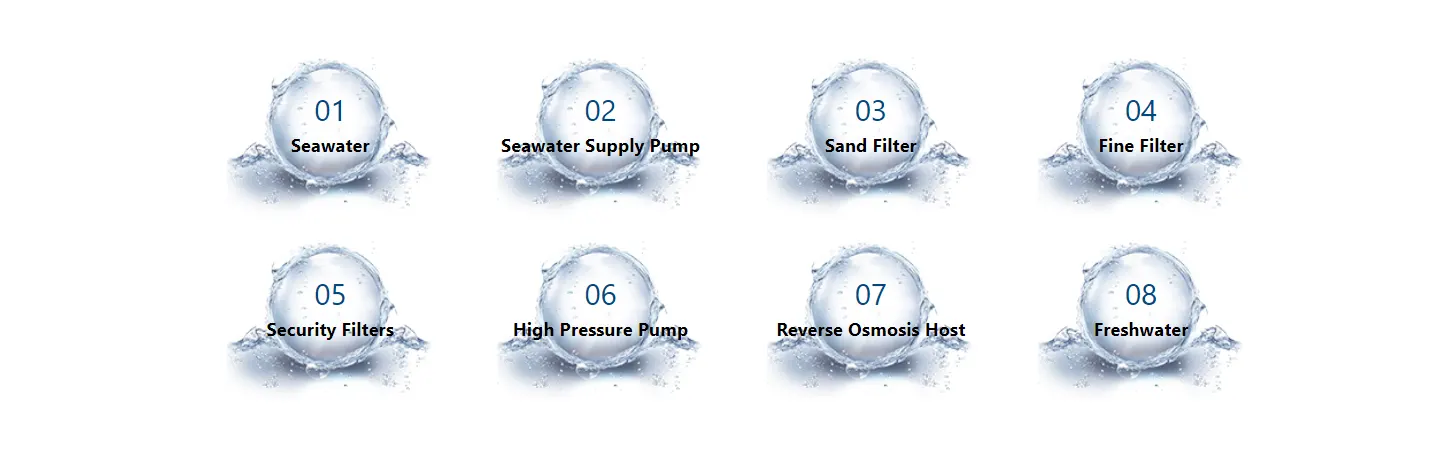

How it works

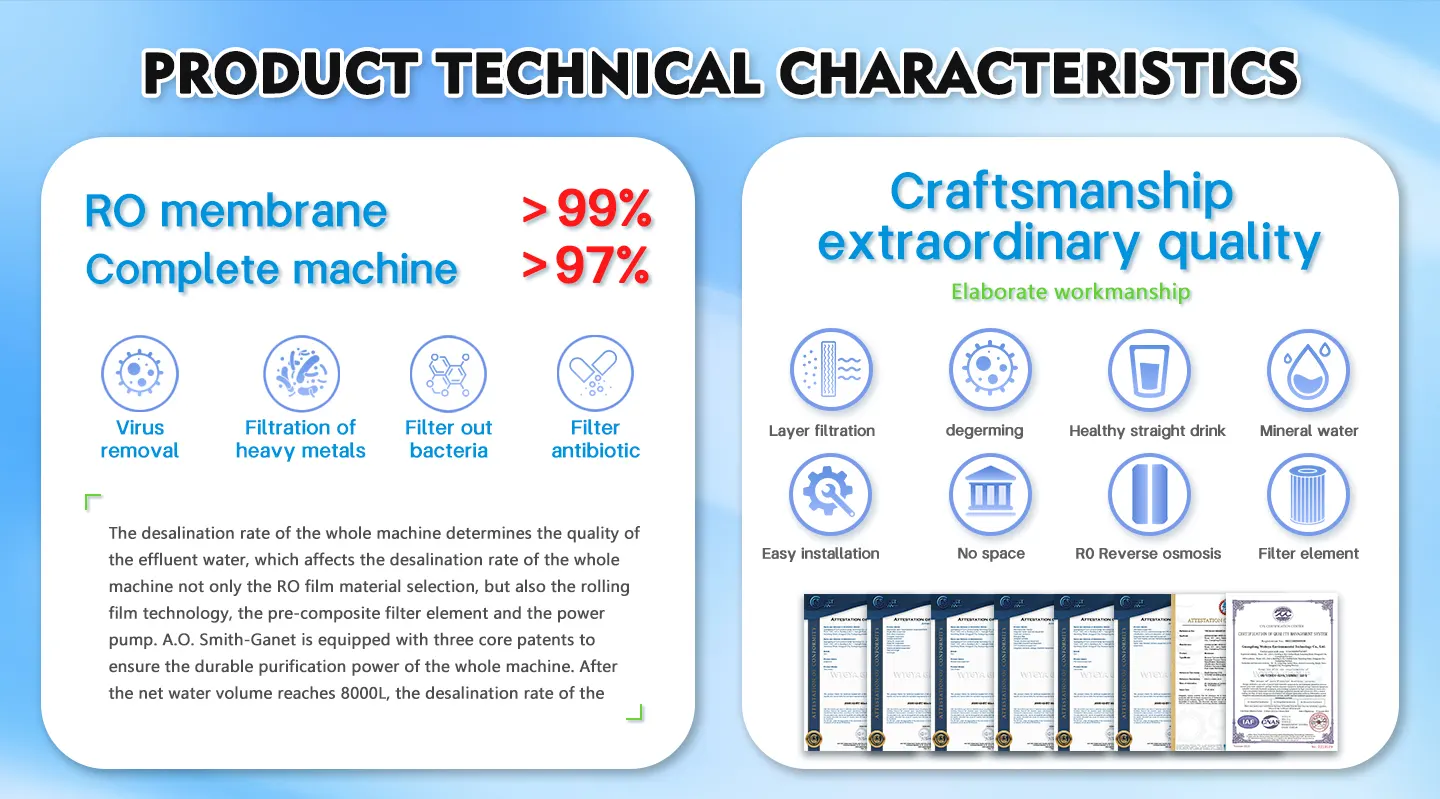

The membrane method mainly uses a semi-permeable membrane to intercept salt and other impurities in seawater and allow pure water to pass through, thereby achieving seawater desalination.The most commonly used technology is reverse osmosis (RO). Under high pressure, seawater passes through a reverse osmosis membrane, which only allows water molecules to pass through, while most of the salt and impurities are intercepted.

What does it consist of

Two Choices - Fresh Water or Drinking Water

You have two different Reverse Osmosis (RO) options, depending on your water needs, available space, and budget. All RO options are compatible with AC PSUs and are available in portable and modular configurations.

Parameter selection

|

Serial number |

Model |

Rated water output |

Dimensions(mm) |

Installed power (kw) |

|||

|

GPH |

GPD |

L |

W |

H |

|||

|

1 |

WTEYA-SWRO-0065 |

65 |

1300 |

800 |

800 |

1600 |

5.3 |

|

2 |

WTEYA-SWRO-0130 |

130 |

2600 |

800 |

800 |

1600 |

5.3 |

|

3 |

WTEYA-SWRO-0190 |

190 |

3800 |

1500 |

800 |

1800 |

6.8 |

|

4 |

WTEYA-SWRO-0260 |

260 |

5200 |

1500 |

800 |

2000 |

9.0 |

|

5 |

WTEYA-SWRO-0520 |

520 |

10400 |

3000 |

800 |

2000 |

16.9 |

|

6 |

WTEYA-SWRO-0790 |

790 |

15800 |

3000 |

800 |

2000 |

23.5 |

|

7 |

WTEYA-SWRO-1320 |

1320 |

26400 |

4000 |

1000 |

2000 |

40.5 |

|

8 |

WTEYA-SWRO-2640 |

2640 |

52800 |

5000 |

1500 |

2000 |

50.5 |

|

9 |

WTEYA-SWRO-3960 |

3960 |

79200 |

6000 |

1500 |

2200 |

74.5 |

|

10 |

WTEYA-SWRO-5280 |

5280 |

105600 |

6000 |

2000 |

2200 |

96.0 |

|

11 |

WTEYA-SWRO-7920 |

7920 |

158400 |

7000 |

2000 |

2200 |

123.8 |

|

12 |

WTEYA-SWRO-10560 |

10560 |

211200 |

8000 |

2000 |

2200 |

149.0 |

Purchase recommendation

|

Project Content |

Economy Edition |

Ultimate |

|

Model |

WTY-ETHD-XXXLPH |

WTY-FEHD-XXXLPH |

|

RO membrane brand |

Well-known domestic brands |

TORAY,DOW,LG |

|

Membrane shell material |

FRP |

FRP |

|

High pressure pump |

Brand: Chinese Brands |

Brand: Danfoss,Little giant,AR |

|

Material: 2205/316L |

Material: 2205 |

|

|

Product equipment form |

Framework |

One-piece sheet metal structure |

|

Control System |

Microcomputer automatic control |

Microcomputer automatic control |

|

Appearance |

Industrial massification |

Exquisite and beautiful |

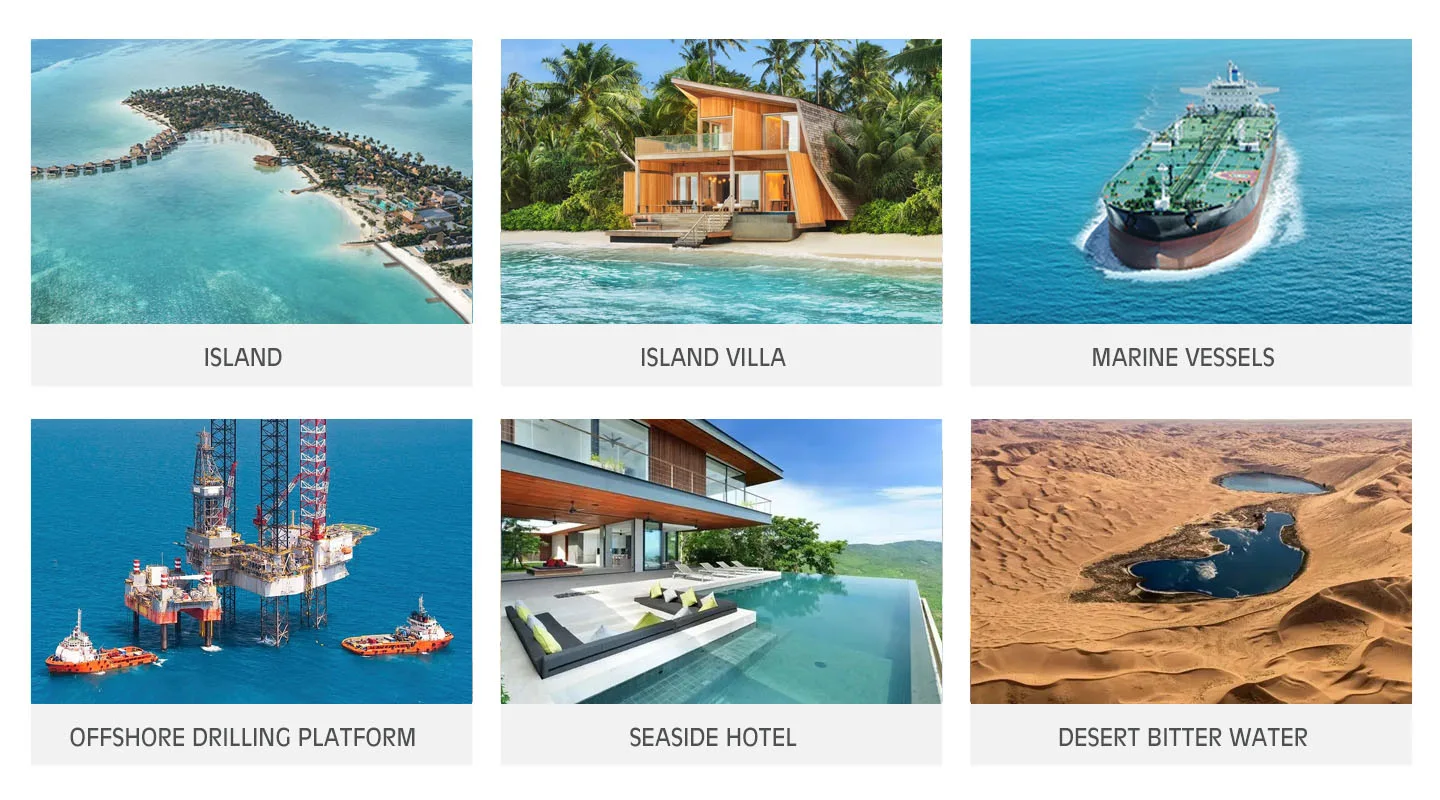

Where it can be used

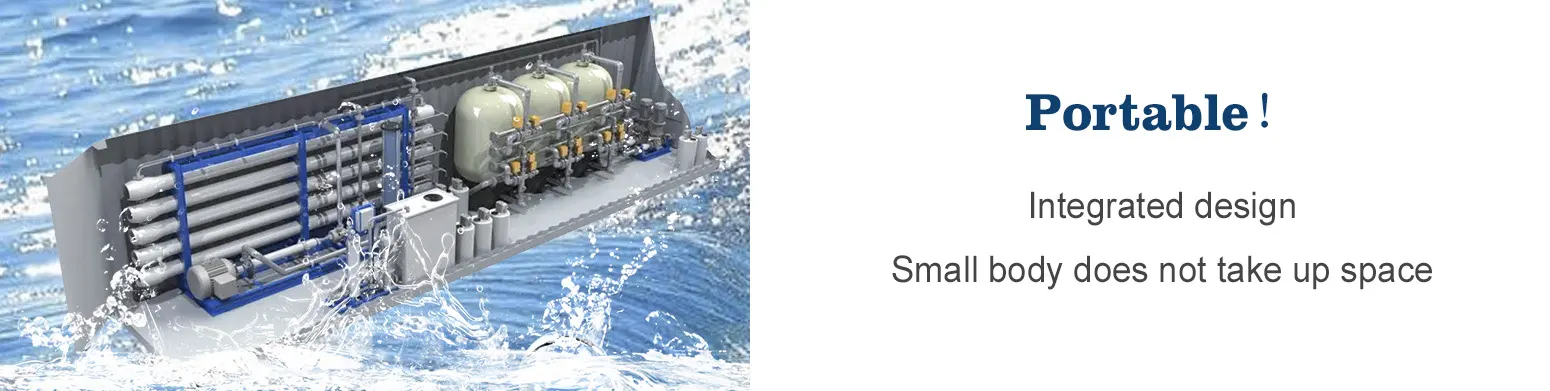

WTEYA's portable desalination plant is a water machine with patented desalination technology. It produces water 24 hours a day to protect your drinking water health! No need to worry about water shortage, stable water production.

WTEYA Manufacturer

WTEYA pursues digital and intelligent manufacturing to provide customers with excellent products and services. We not only provide a series of standardized products that have been rigorously tested and have stable performance to meet a wide range of industry needs. We also provide OEM&ODM customized services to meet the unique needs of customers.

Frequently Asked Questions

|

Questions |

Countermeasures |

| Does the desalination system consume a lot of energy? | WTEYA desalination plant adopts advanced technology, ultra-high water production rate, large flow rate and low energy consumption. |

| Are desalination systems prone to failure? | WTEYA desalination plants use durable materials that are corrosion-resistant and have a long service life. |

| What does desalinated water taste like? |

WTEYA Desalination Plant water is treated to taste the same as WTEYA’s other drinking water. Like dam water, water from the desalination plant is treated to meet Australian Drinking Water Guidelines, which makes it among the best in the world. |

| Is the maintenance cost of desalination system high? | WTEYA desalination plant has an integrated design, a small body and does not occupy space. Installation and maintenance are very simple and low cost. |

| Operator error could lead to system failure | WTEYA desalination plant adopts an automated control system. One-button start and stop greatly reduces the occurrence of failures and accidents. |

|

Why is desalination important?

|

WTEYA desalination plant can turn seawater into drinking water and domestic water in seconds. For islands and coastal cities with scarce water sources, it can ensure a stable supply of fresh water. In natural disasters (such as earthquakes, floods) or disaster relief and emergency situations, mobile or temporary desalination equipment can quickly provide emergency drinking water to ensure the basic living needs of people in the disaster area. |

| Who owns the Plant? | Desalination plant is developed and produced by WTEYA manufacturer. We provide OEM and ODM services, free design, and recruit agents worldwide. |

| What’s the impact on the environment? | The WTEYA desalination plant places a high priority on minimizing its impact on the land and aquatic environments. To support this goal, a rigorous environmental monitoring program is implemented. The plant has minimal impact on the marine environment. |

Desalination plant costing

How much does a seawater desalination plant cost? In order to calculate the cost accurately, we recommend that you fill out a questionnaire and then we will be able to prepare a commercial offer, taking into account all the features of your project. We are always ready to provide you with detailed information about the different models, their technical characteristics, performance. We offer a full range of services, from advice and assistance in selecting equipment to its supply, installation and configuration. Our goal is to provide you with the necessary equipment to effectively solve the water treatment problem in your specific situation.

So, you need to email us at info@wteya.com

Our manager will prepare an excellent quote for you

Previous: Seawater desalination plant