WTEYA is a brand you can trust, with over a decade of extensive experience providing efficient and reliable water treatment solutions to numerous well-known companies worldwide. We have successfully implemented projects for publicly listed companies such as Foxconn, Huawei, Ganfeng, and Rongbai, with over a hundred project cases earning strong trust and praise from our clients. We support OEM & ODM customization, offering tailored solutions to meet your unique needs.

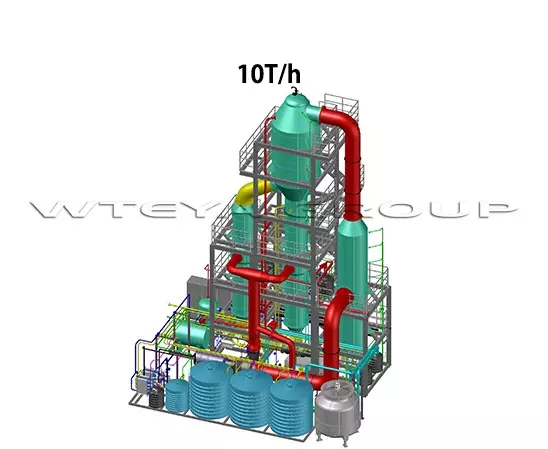

Why the 10t/h MVR Evaporator System is the Must-Have Choice for Large-Scale Wastewater Treatment?

11 Nov, 2025 4:09pm

In today’s industrial landscape, wastewater treatment is not just a compliance requirement—it is a key factor in reducing costs, improving efficiency, and promoting sustainable practices. With increasingly strict environmental regulations and rising energy costs, companies need an efficient, energy-saving, and environmentally reliable solution. Among various options, the 10t/h Mechanical Vapor Recompression (MVR) evaporator system stands out as the core equipment for large-scale wastewater treatment projects due to its outstanding energy efficiency and high processing capacity.

What is a 10t/h MVR Evaporator?

The 10t/h MVR evaporator—also called a 10-ton-per-hour MVR system—is a high-efficiency evaporation device. Its core principle is Mechanical Vapor Recompression (MVR), which compresses secondary vapor generated during the evaporation process and recycles it as a heat source. Compared to traditional single-effect or multi-effect evaporators, the 10t/h MVR system not only offers significant energy savings but also provides high throughput and advanced automation. It is ideal for applications in chemical, pharmaceutical, and food industries for wastewater concentration, crystallization, and drying processes.

Is it really energy-saving?

Absolutely.

The 10t/h MVR evaporator system reuses secondary vapor as a heat source, reducing external energy consumption. Compared to conventional evaporators, energy usage can be cut by 50%–70%.

Energy savings translate not only to lower electricity and steam costs but also to reduced greenhouse gas emissions, making it a win-win solution for both cost efficiency and environmental sustainability.

How does it handle large-scale wastewater?

With a capacity of 10 tons per hour, the MVR evaporator can continuously treat high volumes of wastewater, meeting the demands of large factories:

-

Chemical industry: Efficient concentration of acidic and alkaline waste, reducing hazardous waste volume.

-

Pharmaceutical industry: Solvent recovery and drug solution concentration, improving raw material utilization.

-

Food processing: Concentration of whey, juice, syrups, and other liquids to improve product quality.

This high throughput and multi-purpose functionality enables the 10t/h MVR evaporator to not only manage wastewater discharge but also recover valuable by-products and support resource recycling.

Is it easy to operate and maintain?

Many companies worry about the complexity of large evaporators, but the 10t/h MVR system is designed with user-friendliness in mind:

-

Compact footprint: Despite high capacity, the system is space-saving and flexible to install.

-

Fully automated: Equipped with smart controls that adjust process parameters based on feed and water quality.

-

Easy maintenance: Modular design allows convenient replacement of evaporator tubing, compressors, and condensers, reducing downtime.

This ensures continuous, stable production while lowering operational challenges.

Is it environmentally friendly?

Yes.

The 10t/h MVR evaporator system not only saves energy but also aligns with current environmental standards. By reducing energy consumption, it decreases carbon emissions.

In Zero Liquid Discharge (ZLD) projects, the system can concentrate wastewater to the point of solid-liquid separation, enabling water recovery and minimizing waste. This helps companies meet stringent international and local environmental regulations, making it indispensable for green and sustainable production.

Which industries benefit most?

The 10t/h MVR evaporator system is highly versatile:

-

Chemical industry: Acid/base waste, brine, chemical intermediates concentration

-

Pharmaceutical industry: Drug solution concentration, solvent recovery, wastewater reduction

-

Food & beverage: Juice concentration, syrup evaporation, whey processing

-

Environmental engineering: Municipal and industrial wastewater advanced treatment

Its adaptability makes it an ideal solution across multiple industries and applications.

Why 10t/h MVR Evaporator Systems are Essential for Large-Scale Wastewater Treatment?

-

Significantly reduce energy consumption and operational costs

-

Efficiently handle high-volume wastewater and recover valuable by-products

-

Easy operation and maintenance, suitable for diverse industrial scenarios

-

Environmentally friendly, supporting sustainable development

For chemical, pharmaceutical, and food industries, adopting a 10t/h MVR evaporator is no longer optional—it is the inevitable trend for future industrial development.

Why Choose WTYEA?

WTYEA Is Recruiting Global Partners!

We welcome your partnership. As a brand with nearly 20 years of experience, WTEYA offers various preferential policies, professional training guidance, and comprehensive technical support you can rely on!

👉 Let WTYEA help you achieve unmatched water quality performance!