Solving the evaporation and crystallization problems in high-salt aluminum ash wastewater

With the rapid development of the aluminum processing industry, the harmlessness and resource treatment of aluminum ash have become the focus of the industry. In the wet treatment process, millions of tons of high-salt wastewater are produced each year. Not only are the components complex, but they are also highly corrosive and difficult to control,l crystallization, becoming the key bottleneck restricting the "last mile" of aluminum ash resource utilization. Many companies often face the dilemma of "high energy consumption, strong corrosion, poor crystallization, and high processing costs" after adopting traditional evaporation processes.

✅ Cost-effective solution: WTEYA's innovative technology combination

Through years of technical accumulation and field practice, WTEYA Group has developed a set of high-efficiency, low-energy, and stable integrated evaporation and crystallization solutions to address the complexity of aluminum ash wastewater. It places special emphasis on cost-effectiveness and has become a hot-selling product among customers in multiple industries.

✅ Energy consumption control: TVR+MVR coupling energy-saving system

The steam jet heat pump (TVR) and mechanical vapor recompression (MVR) coupling technology is used to automatically adjust the compression ratio according to the fluctuation of wastewater salinity, achieving:

>> Energy consumption per ton of water is stably controlled at 70-85kW/h

>> System operation saves more than 30% of energy

>> No need for external steam, greatly reducing operating costs

✅ Equipment anti-corrosion: dual guarantee of materials and processes

The Cl⁻ content in high-salinity wastewater is extremely high and highly corrosive. WTEYA has:

>> The main equipment uses titanium-palladium alloy TA10 (chloride ion concentration resistance ≤ 15%)

>> Super stainless steel is used for the flow-through parts

>> Laser cladding anti-corrosion technology is used for key welds

Ensure stable operation of the equipment for more than 5 years, reducing the frequency of replacement and maintenance.

✅ Crystal purity breakthrough: intelligent control + structure optimization

To solve the problems of high impurities and high water content in traditional crystallization, WTEYA developed:

>> Forced circulation anti-scarring system

>> Mother liquor reflux gradient purification device

>> Centrifugal drying integrated unit

The output industrial salt has high purity and high market recovery value.

✅ Pre-processing collaborative system: improving overall processing efficiency

To ensure the stable operation of the backend system, WTEYA provides comprehensive pre-processing support:

>> Establish an automatic water quality detection system

>> Ensure that the water production is stable and meets the standards

✅ Why choose WTEYA Group?

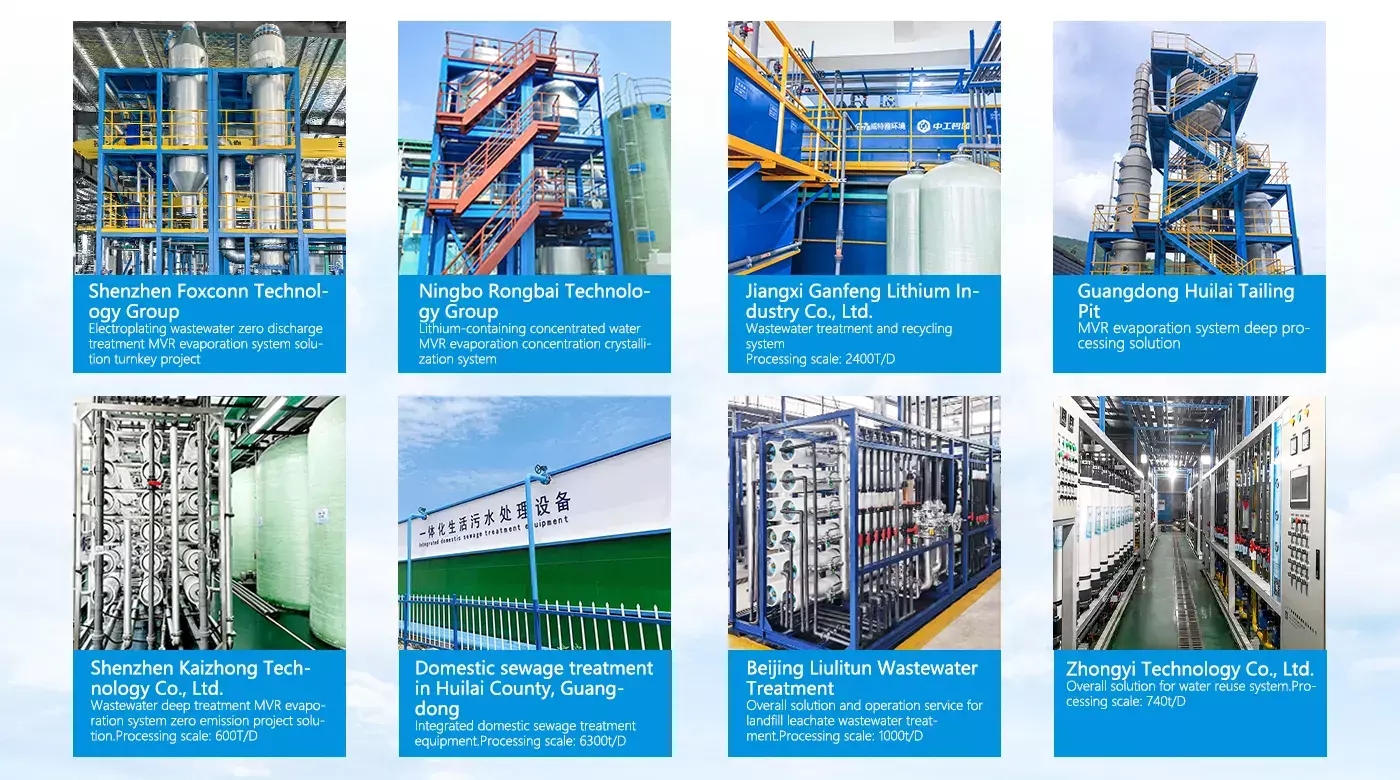

WTEYA is a brand you can trust. With more than ten years of rich experience, it has provided efficient and reliable water treatment solutions to many well-known companies around the world. It has successfully implemented projects for listed companies such as Foxconn, Huawei, Ganfeng, and Rongbai, with more than 100 project cases, and has won the trust and praise of customers. Support OEM & ODM customization, customized solutions to meet your unique needs.

✅ WTEYA is recruiting agents!

Welcome to join us. As a 16-year-old brand, WTEYA provides you with a variety of preferential policies, professional training guidance, and all-around technical support, which is worthy of your trust!

*Email: info@wteya.com

*WhatsApp:+86-18002840855

Let us help you achieve unparalleled water quality!