MVR Evaporator Boosts Efficiency of New Energy in Sustainable Systems

As global industries prioritize sustainable development practices, MVR (Mechanical Vapor Recompression) evaporators offer an intelligent, efficient, and environmentally friendly solution for industrial wastewater management and resource recovery. Their application in new energy manufacturing processes not only reduces environmental impact but also significantly enhances operational efficiency.

🌱 Driving Sustainable Industrial Processes

MVR evaporators compress and reuse vapor generated during the evaporation process, greatly reducing reliance on external heat sources. In fields such as battery manufacturing, photovoltaic materials, and hydrogen energy projects, this translates to significant energy savings, lower carbon emissions, and reduced dependence on fossil fuels—critical factors for achieving a green future.

💧 A Powerful Tool for Wastewater Resource Recovery

The new energy industry produces wastewater with high salt content and complex organic compounds during production. MVR evaporators efficiently concentrate this wastewater, enabling the recovery of reusable water and valuable salts while ensuring compliant discharge. This robustly supports enterprises in achieving "Zero Liquid Discharge" (ZLD) goals, which has become a global benchmark for sustainable manufacturing.

🔁 Efficient Operation within a Closed-Loop System

One major advantage of MVR evaporators is their support for closed-loop operation. By recovering thermal energy and reducing fresh energy consumption, they perfectly align with the circular economy concept. Their compact footprint and low operating costs make them especially suitable for next-generation clean energy facilities such as solar panel factories and lithium battery production lines.

📉 Energy Saving, Cost Reduction, Emission Cut, and Efficiency Improvement

In the long term, MVR evaporators represent a highly cost-effective investment. Lower energy consumption results in reduced electricity costs, and emission reductions help companies achieve carbon neutrality goals. As environmental regulations continue to tighten, deploying MVR systems is no longer optional but essential.

🔧 Scalable and Intelligent Technology

Modern MVR evaporators are equipped with automatic control, real-time monitoring, and modular design, allowing flexible adaptation to varying site conditions, flow rates, and process demands. For enterprises committed to building flexible, future-oriented green factories, MVR technology is undoubtedly a strategic asset.

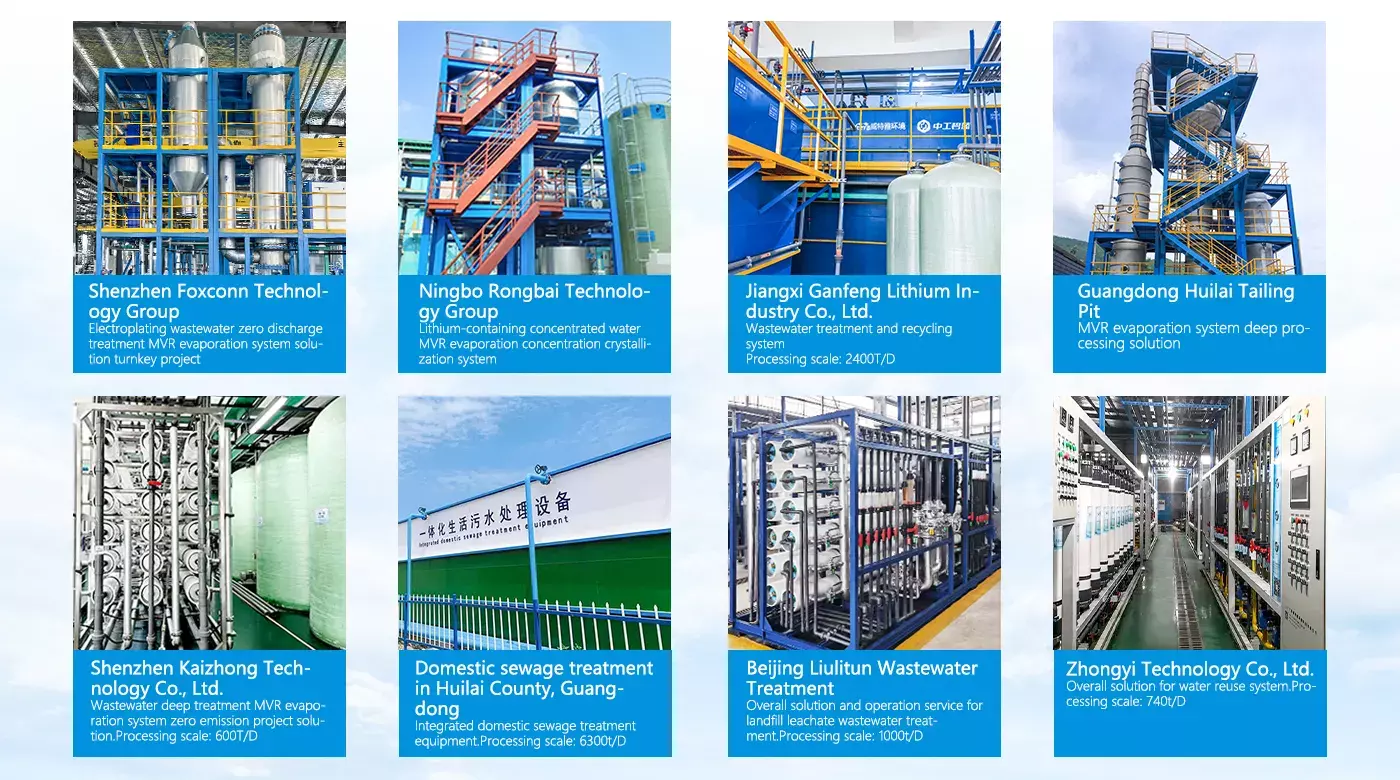

Why Choose WTEYA Group?

WTEYA is a trusted brand with over a decade of rich experience, providing efficient and reliable water treatment solutions to many well-known global companies. We have successfully completed projects for listed companies such as Foxconn, Huawei, Ganfeng, and Rongbai, with over 100 project cases highly praised by customers. We support OEM & ODM customization, offering tailored solutions to meet your unique needs.

WTEYA Is Recruiting Distributors!

Welcome to join us. As a 16-year-old brand, WTEYA provides you with a variety of preferential policies, professional training guidance, and all-around technical support, which is worthy of your trust!

*Email: info@wteya.com

*WhatsApp: +86-18002840855

Let us help you achieve unparalleled water quality!