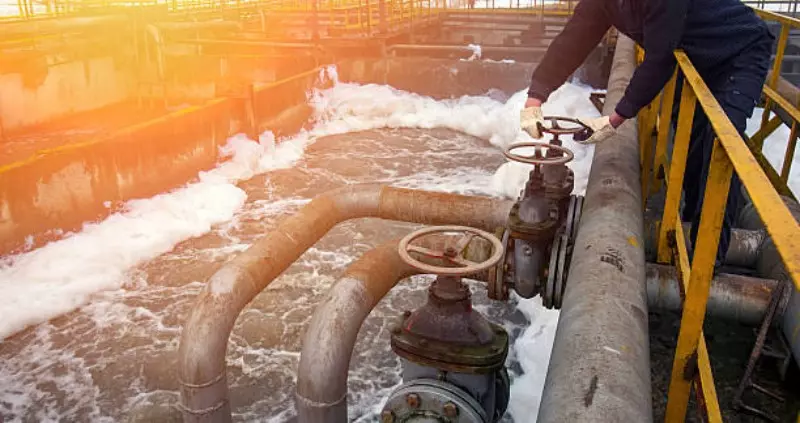

Innovative Models and Technical Pathways for Wastewater Treatment in Chemical Industry Parks

In recent years, wastewater treatment in chemical industrial parks has become both a critical and challenging focus of environmental management. Due to the long industrial chains, complex processes, and diverse, high-concentration pollutants in chemical production, conventional treatment methods often struggle to meet discharge standards or reuse demands.

WTEYA Group is advancing the sector with innovative technical pathways and integrated management models to help chemical parks build efficient, low-carbon, and sustainable wastewater treatment systems.

🔬 Key Challenges in Chemical Park Wastewater Treatment

Wastewater from chemical industrial parks typically contains high concentrations of COD, ammonia nitrogen, refractory organics, saline wastewater, heavy metals, and various toxic pollutants. It is characterized by complex composition and large fluctuations in both quality and quantity.

Treatment faces numerous challenges such as high loads, biological system instability, and elevated operational costs, which call for systematic, modular, and intelligent solutions.

⚙️ WTEYA’s Innovative Treatment Framework

WTEYA has developed a multi-stage collaborative treatment system tailored to the "high difficulty and diversity" of chemical park wastewater. This system revolves around:

-

Source separation & classification collection

-

Pretreatment

-

Advanced oxidation

-

MVR evaporation / membrane concentration

-

Water reuse or zero liquid discharge (ZLD)

By combining front-end source control with end-point integration, the approach aims to align pollution reduction, system stability, and economic feasibility.

Core Technology Highlights:

-

Source-separated treatment: Classify wastewater streams (saline, organic, nitrogen-rich) to improve overall efficiency

-

Efficient pretreatment: Includes flotation, Fenton oxidation, coagulation, and sedimentation to reduce downstream burden

-

MVR Evaporation Technology: Energy-efficient recovery of water resources; enables volume reduction or crystallization solidification

-

Smart control platform: Enables automated process switching, load adjustment, and remote operation & maintenance

🌍 Green Parks & Water Resource Reuse

With WTEYA’s integrated solutions, chemical parks can not only achieve compliant discharge but also reuse treated water for cooling tower makeup, cleaning processes, landscaping irrigation, and more.

This supports the development of green circular industrial systems, improves ESG performance, and helps enterprises obtain green certifications.

📈 Innovative Management Models for Cost Reduction and Efficiency

WTEYA also offers collaborative park-wide treatment models, such as:

-

BOT (Build-Operate-Transfer)

-

EPC+O (Engineering, Procurement, Construction + Operation)

-

Third-party professional operation services

These approaches help reduce initial capital investment and operational complexity, while enhancing system stability, safety, and economic efficiency across the park.

🔧 Why Choose WTEYA Group?

WTEYA is a trusted name in the field of industrial water treatment, with over a decade of proven experience. We have successfully implemented high-performance projects for leading companies such as Foxconn, Huawei, Ganfeng Lithium, and Ronbay Technology, earning industry-wide recognition.

We provide OEM & ODM customized solutions, tailored to your specific needs and operational conditions.

🤝 WTEYA Is Recruiting Global Distributors!

Join us! As a trusted 16-year brand, WTEYA offers:

-

Attractive partnership policies

-

Professional training & technical guidance

-

Full-spectrum technical support

We're committed to building long-term value with our partners!

📧 Email: info@wteya.com

📱 WhatsApp: +86-1800 2840 855

Let WTEYA help you achieve unparalleled water quality — together, toward a greener future.